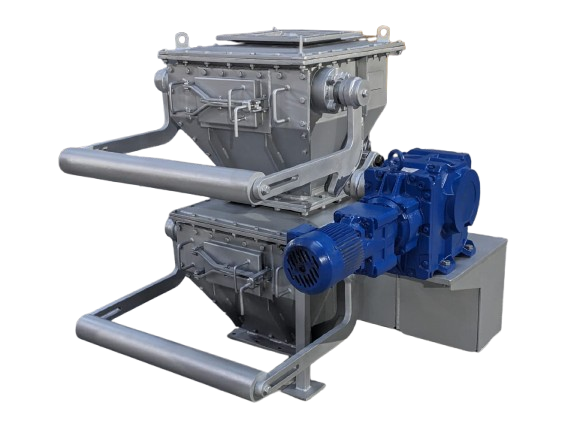

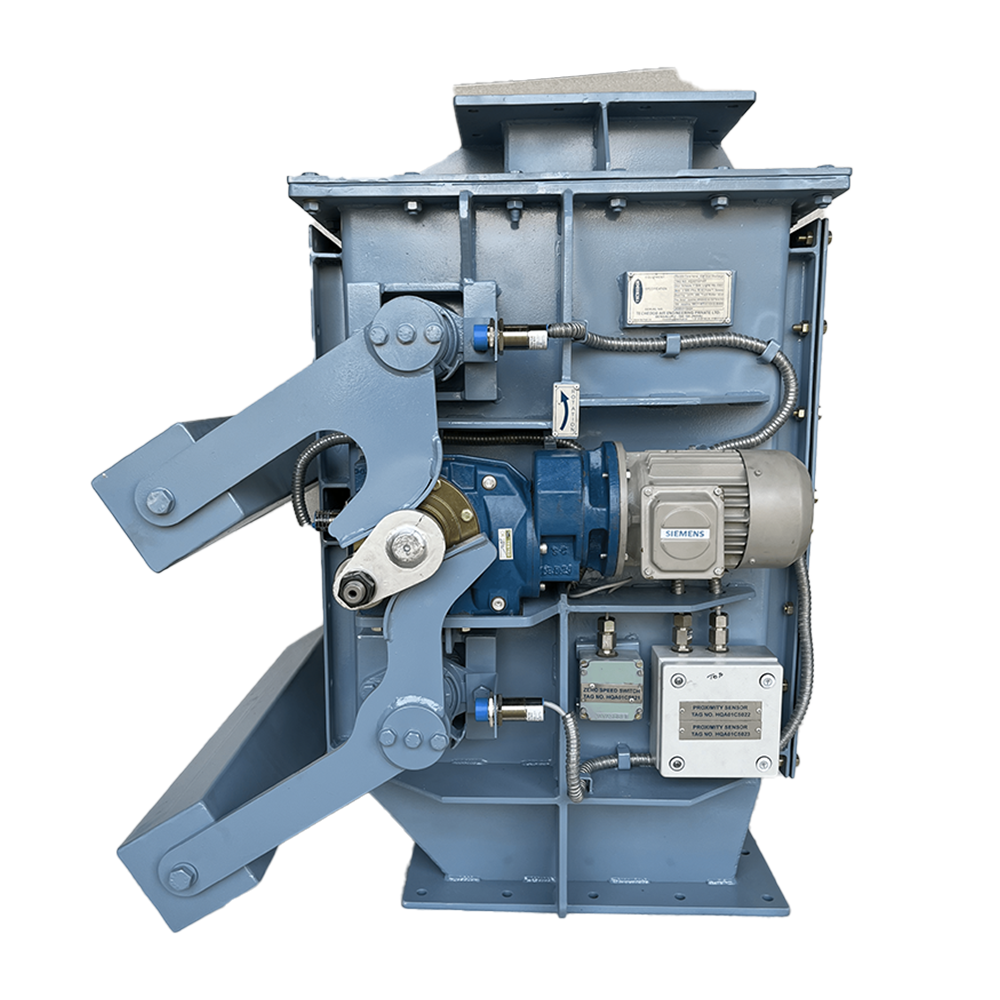

Double Cone Valves

Robust and reliable valves for Sinter Dust discharge in Steel Industry Sinter Plants.

Product Specifications

Primary Application

Sinter Dust discharge under high negative pressure from Waste Gas Main and ESP.

Available Sizes

200NB, 250NB, 280NB, 315NB, and 400NB

Supply History

Over 570 Double Cone Valves (DCVs) supplied

Material Construction

Sealing Cone and Ring of NiHard/HiChrome Cast (500–600 BHN)

Manufacturing Precision

Sealing surface CNC machined for near zero clearance

Operation Mechanism

Geared Motor and Cams arrangement

Distinctive Features

Extreme Durability

Constructed with high-hardness materials to withstand abrasive Sinter Dust and high temperatures.

Superior Sealing

CNC machined components ensure minimal leakage, crucial for high negative pressure applications.

Proven Reliability

With over 570 units successfully operating, our DCVs are a trusted solution in the steel industry.

Wide Range of Sizes

Available in multiple sizes to suit diverse plant requirements and capacities.